Furnace Cost Calculator estimates the cost of replacing your old gas/propane furnace with a new High Efficiency Furnace with an ECM motor, and one or two stage or modulating gas burner.

Get local price quotes from HVAC / heating contractors near you.

Price estimates are based on your home size, heat load, furnace AFUE rating & heating capacity in BTUs.

Calculate Gas Furnace Cost & Size in Ohio

See costs in your area

Start Here - Enter Your Zip Code

See costs in your area

Start Here - Enter Your Zip Code

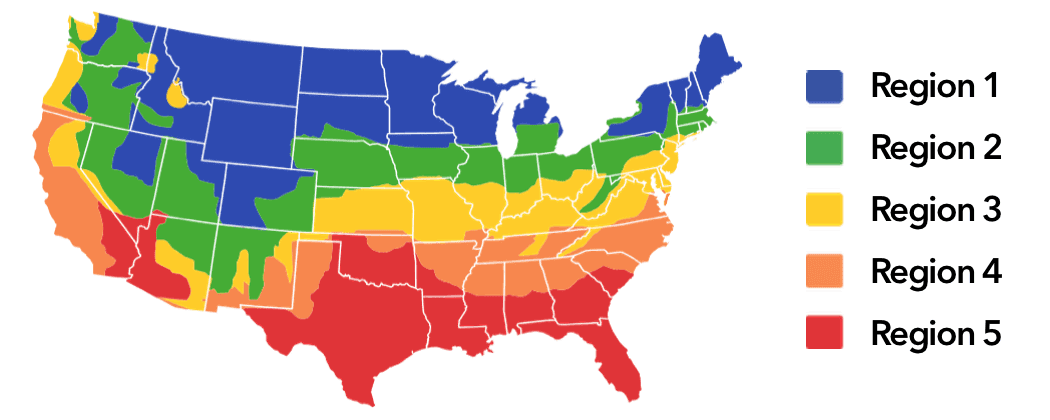

Climate Region / Zone: Your estimated location is Ohio - Climate Region #3

Your location on the climate zone determines the heat load needed for your furnace.

Some states have multiple climate zones/regions. Please adjust your climate region as needed - see map below:

Gas furnaces are the most common type of home heating systems in the US. If you a Central AC with air ducts, you most likely have a gas furnace to go along with it, for the heat. Gas furnace make warm air, which is then distributed through the air ducts system.

Furnace Replacement Cost Results

Once you enter your home size and select furnace efficiency, you will get the recommended unit size (heating capacity) in BTUs, as well as 3 price estimates – Low, Medium and High.

Furnace “size” or heating capacity will automatically adjust based on the heat load in your state. You can override this, by selecting your “Climate Region” based on the map above.

The price estimates do include labor/installation cost as well as all standard equipment, materials and parts. Prices are adjusted for inflation, and have been updated for 2023.

As of Feb. 2023, national average in US, to install a 96% AFUE furnace is $4,810 – $6,230. Price vary depending on your state, and are automatically adjusted during calculation, based on your location.

Furnace Efficiency

What is Furnace Efficiency (AFUE)? In simple terms AFUE represents amount (percentage) of heat produced by burning Natural Gas / Propane / Heating Oil, and retained by your furnace to heat your home. The rest goes “out-the-chimney”.

For example, a 96% AFUE furnace will use 96% of heat, and 4% will be lost in as exhaust gas. An 82% AFUE furnace will waste 18% of heat as exhaust gas.

High Efficiency furnaces use double heat exchanger, where exhaust gases pass through 2nd condensing exchanger, and extract additional 14-16% of heat, reducing waste to mere 2-4%.

Standard efficiency furnaces (80-84%) have only 1 heat exchanger, and thus do not recapture heat left in the exhaust gases.

Besides the efficiency of the furnace itself, you have additional place to “waste” heat, and those are your air ducts.

Air Ducts Losses: Because your air ducts add certain amount of heat loss, it is extremely important to have a high efficiency furnace, since heat loss is compounded. According to US Department of Energy (DOE) and EnergyStar, duct heat loss can be as high 20-30% and at least 10% on the low end, even with insulated ducts. In fact, EnergyStar recommends to insulate your ducts with R-6 to R-11 insulation to reduce leaks and losses.

To make it easier to understand, if you have 20% loss in the ducts, and use an 84% AFUE standard efficiency furnace, your combined loss will be 36% (20% + 16%). That means that over 1/3 of your heat is waisted.

Therefore, having a 96% furnace is very beneficial. While there are furnace models as efficiency as 98%, the extra 2% AFUE is usually not worth the extra cost, which can be as much as $1500-2000 extra.

It’s better to spend the extra money on insulating your ducts, which can yield improvements of as much as 10-15% in efficiency, for the same cost.

Problems with High Efficiency Furnaces

So the biggest issue, is the “comfort level”. Furnaces can be 1 stage, 2 stage or modulating. This means they can provide 100% of heat all the time (1 stage), or 60/100% of heat depending on load (2 stage) or variable percentage 25% to 100% of heat, depending on load.

A 1 stage furnace is the worst, because it will run in short bursts at maximum speed, and then shut off. What you will experience is periods of extreme heat (when furnace is running) followed by feeling cold for a period of time, when furnace is not running. Usually you will feel more cold, and will be very uncomfortable, and very unhappy.

This problem will be exacerbated by an ECM motor, that is “very efficiency” but runs very fast, to provide the needed CFM (cubic feet / minute) of the air flow. Once again – short burst of heat, followed by a period of cold.

Therefore, it is much better (and arguable economical) to run at 50-60% output, for longer, making homeowners more comfortable, producing less noise (lower air flow), and reducing duration of OFF periods, when you feel cold.

That’s where a 2 stage furnace is much better. Of course a variable speed furnace is the best, but the cost becomes prohibitive for many.

However, all these comfort and efficiency enhancements, come with a hidden cost. As furnace internal components become “better”, they get more complex, and are more prone to breaking. Since they are more complex, they are naturally more expensive.

My furnace is 39 years old and has the original blower motor on it. Sure it’s a terrible furnace, with 155K BTUs output and 69% AFUE, but it works. I don’t use it any more, since I completely switched to Heat Pumps, but still have the furnace for backup heat (in case my power goes out), I can always connect furnace to a generator, and have the heat.

Another problem – ECM Motors

Let’s take for example ECM motor. On the old furnaces you had a basic one speed motor, that could last 20-40 years, and costs $200-300 depending on model.

An ECM motor will cost $800-1000 just to buy (see for yourself), and these darn things happen to break more often then the good old 1 speed motor.

What’s even worse – you have to use ECM motor on the furnaces. You can’t just put an el-cheapo any kind of motor. Has to be specific model number, that only works with your furnace. Oh, and when ECM motor breaks, it will be in a middle of a snow storm, and you will usually have to wait 2-3 weeks, because no supplier will have it in stock.

Besides the cost and tendency to go bad on you in the worst possible time, ECM motors run at very high speeds, to have HICH CFM, which as we mentioned before, will make your Heat-ON cycle short, and then, cold OFF cycle, until thermostat decides it’s time to go on again.

Bottom line, it takes a good furnace installation technician to fine-tune your 2-stage or variable furnace, to run at lower output for longer, and to have shorter off cycles, to provide continuous warmth, and minimize gas costs. Those installers are very rare, and unfortunately your will likely get the opposite.

Is it really that bad? What is the solution?

Is it really that bad? Well, not completely terrible, but also not great either. As I just said above, you need a really good installer to properly setup the balance between motor speed, furnace heat output, and thermostat ON/OFF cycle duration, to make a furnace heat comfortable.

Also, no anyone can guaranty that your ECM blower motor will not die on you at worst possible moment. Do they all break after 3 years? No, but too many do, and therefore, it is to be expected.

What’s the solution? You will be surprised, but the solution is hot water BOILER – condensing or standard. Boiler provides much more comfortable heat with minimal up/down variance, almost no noise, and is MUCH more efficient.

But I came here for a furnace price … Yes you did, but boiler is much better 🙂

It does cost more, as you will also need radiators, but I know a bunch of people that switched, and are VERY happy.

In fact, even with extra expense for radiators, considering that cost of new Furnace is about the same as new Boiler, you will recoup the extra cost in savings from reduced gas consumption (that 10-30% loss in ducts adds up quickly).